Rilsan® Protective Covering

Rilsan® is very simply a fine powder which is thermally fused to a metal surface to create a very hard wearing protective coating.

No protective coating comes close to matching that of Rilsan®

Rilsan® is very simply a fine powder which is thermally fused to a metal surface to create a very hard wearing protective coating, which offers many advantages, including:

- Resistance to scratching, impact (high), abrasion / wear. chalking, corrosion (excellent), solvents and weathering.

- Low surface friction.

- Long life.

- Electrical insulation.

- Smooth glossy finishing, helping to repel dirt and ensure easy cleaning.

- Good hygienic properties (good food contact qualities).

- Attractive finish (smooth and glossy).

Rilsan® is the ideal alternative to painting, galvanising, enamelling and chrome plating, when it comes to protecting metal surfaces, making it ideal for use in a diverse range of applications / industries for the protection of critical metal components (and surfaces), including:

- Food.

- Print.

- Effluent treatment.

- Automotive.

Rilsan® offers higher levels of abrasion and impact resistance than that of PVC, polyethelene, epoxy finishes and oven-cured paint.

At AMC, we only use original Rilsan® powder. Beware of imitations.

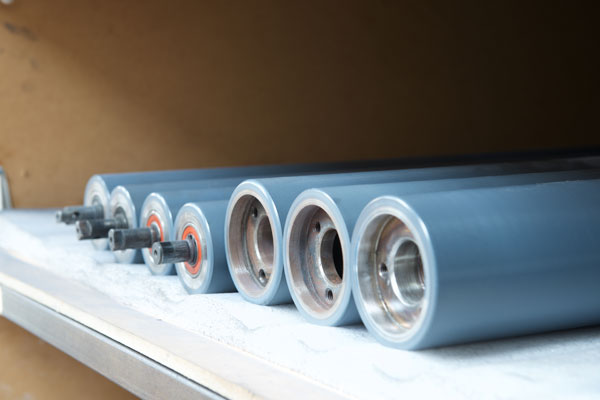

Offset printing

Rilsan® roller covering (often referred to as Nylon or plastic) is specified by such press manufacturers as Heidelberg, Roland and Goss. Many presses benefit greatly when their old copper or chrome coated rollers are recovered with Rilsan®.

Substantial savings can be obtained by recovering worn out steel knurled rollers in Rilsan®, against that of new replacement rollers.

Only original Rilsan® powder is used (as specified and supplied by all leading press manufacturers). Beware of imitations.

Advantages in print

- Saves you money.

- Longer life.

- Abrasion, wear and solvent resistance.

- Not affected by inks, damper and wash up solutions.

- Resists ink build up.

- Extends life of wash up blades.

- Improved print quality.

- Potential to run press at higher speeds.

The service

Our quality, service and turnaround are second to none.

Standard delivery is 3 days, but rollers can (subject to prior arrangement) be turned around in 24 hours if required.

Rollers can be supplied complete for most litho printing presses at a fraction of OEM prices.

We offer an exchange service for Heidelberg Z Rollers.

Including: SM102, SM74 and SM72).